During November 2019, the plant was operating at full capacity. The material and labor costs of Job No. 101 and all other jobs worked on in November are shown below. Helps in spotting cost trends, gauging production efficiency, and facilitating data-driven financial decisions.

Would you prefer to work with a financial professional remotely or in-person?

Prepare Process Accounts showing cost per ton of each process. The scrap value of the wastages in process X is Rs.8 per 100 units and in process Y is Rs.10 per 100 units. Take self-paced courses to master the fundamentals of finance and connect with like-minded individuals. We need just a bit more info from you to direct your question to the right person. Our goal is to deliver the most understandable and comprehensive explanations of financial topics using simple writing complemented by helpful graphics and animation videos. Of the former, 50% was transferred to Job No. 202 and the whole of the remaining plant was returned to stores.

All Rights Reserved © 2024 IBN Technologies Ltd

Job costing is ideal for industries producing unique, custom-made units, whereas process costings caters to sectors with standardized, continuous production. While both systems utilize similar journal entries, process costing is deemed suitable for many industries due to its adaptability. It allows for easy transition to job costing or even a hybrid approach, without roth ira contribution limits in 2021 significant restructuring of the chart of accounts. In the intricate world of financial accounting, understanding the cost structures of products is paramount. “Process Costings” stands as a beacon for industries that thrive on standardized production. But, like all methodologies, it comes with its own set of challenges that require effective solutions.

What information is included in a job cost sheet?

Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others. Process cost accounting is commonly applied when dealing with uniform product units. To better understand its application, let’s consider a hypothetical scenario. Production Overhead is absorbed by processes at a percentage of direct wages. There was no stock of raw materials or work-in-progress at the beginning or at the end of the month. In this article we will discuss about the top five problems on process costing with their relevant solutions.

How confident are you in your long term financial plan?

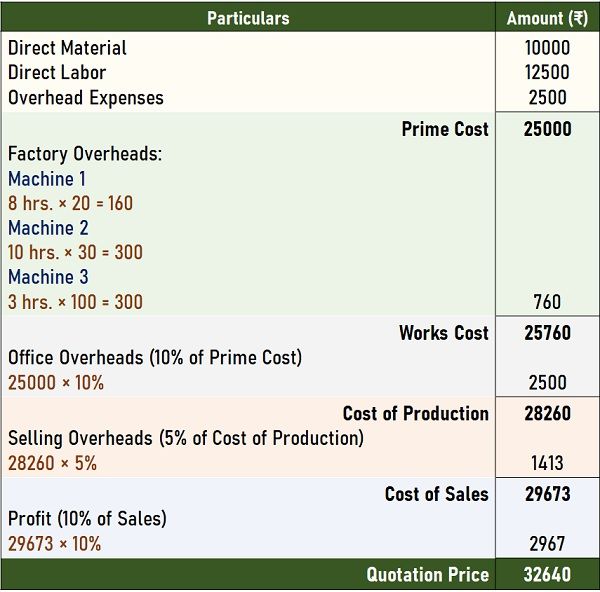

The expenses shown below were incurred for a job during the year ended on 31 March 2019. Simplifies the auditing process and ensures alignment with regulatory mandates.

A machine costing $5,500, specially brought for this contract, was also sold for $2,000 in December 2019. Of the balance of this account standing on 30 November 2019, $61,500 was in respect of plant and machinery. The respective job accounts showed the following balances in the contract ledger on 30 November 2019. For the remainder of the balance on plant and machinery, $40,000 was used on the job for 8 months and the rest for 6 months. The overtime premium should be charged fully to Job No. 101 if it was a rush job and it was done at the request of the customer.

- While both systems utilize similar journal entries, process costing is deemed suitable for many industries due to its adaptability.

- The respective job accounts showed the following balances in the contract ledger on 30 November 2019.

- Example- Aero Labs manufactures wind tunnel systems designed for use by educators and researchers, including organizations like NASA.

- In this article, we’ll unravel the necessity of process costing, explore the obstacles it presents, and delve into strategies to overcome them, ensuring a streamlined and efficient costing system for businesses.

- The company’s profit and loss during November will be affected by the choice of any method if all the jobs performed during the month are not completed by the end of the month.

- R Discuss the various methods of valuation of work in process.

This production involves the acquisition of various raw materials, including fans, vanes, base EWT parts, motors, as well as paint and hardware. These raw materials, like fans and vanes, are continuously used throughout the production process, resulting in the creation of identical wind tunnels. For businesses employing process costing, the products are often homogeneous, which means the products are identical or very alike. This homogeneity simplifies the costing process, eliminating the need for individual product cost tracking. Our writing and editorial staff are a team of experts holding advanced financial designations and have written for most major financial media publications.

R State the meaning and treatment of Inter-process proots. Job order costing is a method of accounting for manufacturing costs using a specially designed set of accounts. It is based on the assumption that manufacturing activities are undertaken to fulfill specific customer orders or contracts. Job costing is the method of allocating production costs to specific jobs. Example- Aero Labs manufactures wind tunnel systems designed for use by educators and researchers, including organizations like NASA. Typically, they produce and sell 7-8 wind tunnels annually.